We missed you Bill ....stayed home due to C-19?

27 May 3, 2020 11:06 am

Re: This is the Can Am page. (116 replies, posted in Rapid Raceway)

Sure glad you held this CanAm race and 12 people showed up! I felt a need to be there, as who knows when the next CA race is going to be now that we are entering the off season and CA may not be voted in for a few years? Gobs of fun and glad I was able to be a part of it. Now my 4 cars will have to go into some kind of cryogenic preservation mode.

28 April 29, 2020 9:04 am

Re: WTB. LATE MODEL NASCAR (6 replies, posted in Rapid Raceway)

I have 2 brand new Ford Fusion bodies and set of decals ...... probably won't use. $15 each if interested.

29 March 10, 2020 3:53 am

Re: Springwater Classic NASCAR 500 (14 replies, posted in Springwater Raceway)

Post race remorse ..... not showing up to this event. Brings back lots of memories racing on identical and similar Olgilvie tracks ... 8 lanes of high speed action. My 1990 Lumina Nascar was in the box ready to go ... just needed to jump in my Van and head south on I-5 for a couple hundred miles.

30 February 11, 2020 1:31 pm

Re: This is the Can Am page. (116 replies, posted in Rapid Raceway)

Thanks Dennis, it is an easy car to drive fast!

Obviously the potential is there for a flexi chassis'd car, just have to mind the details.

Was a fun race, thanks for coming down!

Zack

Is that body on the CA list? Looks similar to a 962 to me. What's the weight? Is it full width 3.25"? I might have to get one ... to catch you if I can. ![]()

31 February 9, 2020 2:12 pm

Re: This is the Can Am page. (116 replies, posted in Rapid Raceway)

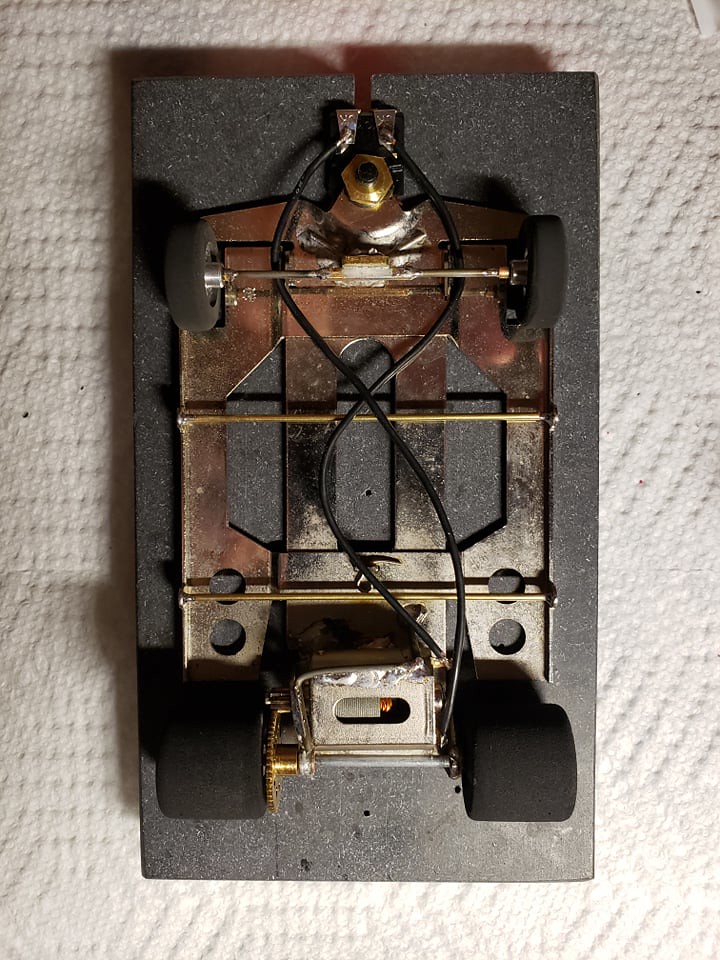

Here are some pics of a car I put together using one of Bill's used Chassis's. I did a center mounted axle to give just a little bit of flex up there, small tire, and bracing on the pan between the rear bushing mounts.

Body is a Betta & Classic 917/30. Just waiting on decals.

Looking forward to testing a couple cars on Saturday at Rapid!

Zack

AND THE WINNER IS ..... this basic and simple to build CanAm car!! ANYONE can do these simple MODS on an old Champion or Jk flexi and have a great CanAm race car at Howie's. Will it also run strong at Inslot? If so, fantastic. I am all in favor of simple solutions to complex problems. My custom built car might have been a few tenths faster ... I think I saw a 4.00 second lap time and I was trying to stay IN and out of trouble more than I was trying to cut a track record lap. Little did I know that Zack with his modified flexi was ripping off huge lap totals! Never heard of such a thing ... but glad it happened. That car is easily duplicatable and other racers can use it to go faster and be a contender!

32 January 26, 2020 10:45 pm

Re: PASER Race at Inslot's Checkered Flag on January 25, 2020. (7 replies, posted in PASER)

Congrats to Gearloose for the Nascar win!!!!! I thought I heard the comment this is his first Nascar win on that track. Not bad for an 84 year old who is just starting to reach his full potential.

33 January 22, 2020 4:13 pm

Re: The NASTE chassis! (49 replies, posted in Rapid Raceway)

This looks like a well thought out improved version. 3/32 bearings are 1/4" OD I believe without looking. Using durable steel in the critical areas is a big plus. Brass provides good weight but usually needs wire re-enforcement. Good job on trying to provide a production kit that doesn't need a lot of mods!

Oops, 3/16 bore is correct.

34 January 22, 2020 4:03 pm

Re: The NASTE chassis! (49 replies, posted in Rapid Raceway)

This looks like a well thought out improved version. 3/32 bearings are 1/4" OD I believe without looking. Using durable steel in the critical areas is a big plus. Brass provides good weight but usually needs wire re-enforcement. Good job on trying to provide a production kit that doesn't need a lot of mods!

35 January 8, 2020 7:41 pm

Re: This is the Can Am page. (116 replies, posted in Rapid Raceway)

Dennis; are you going to give me a chance to tech your fine chassis after all? Go ahead "MAKE MY DAY", although I will keep my pistol in my holster..............................................................maybe!

Of course you can tech my fine car there Howie! You will see I have nothing to hide .... ie. same as the pics I shared. Plenty of ground clearance and plenty of front end tension to support the weight of the front of the car even if a guide flag wasn't there. But of course there WILL be a guide flag and it will also support the front of the car ... so as to maintain .055" or more clearance.

The whole car weighs less than 4 ounces ... and the front of the car weighs less than 2 ..... so not a lot of tension is needed to support the weight. A have a combined 4 oz of tension plus the guide ... to support 2 oz of nose weight keeps the bottom side nice and shiny.

36 January 7, 2020 3:16 pm

Re: This is the Can Am page. (116 replies, posted in Rapid Raceway)

I have never ran my CanAm cars at Howie's ... to see how they go. I know they run strong on Bostick's track. I am modifying another old JK flexi similar to what you ran at Bill's ... to see how it runs at Rapid. I'll be running a more scale McLaren M7 I think with a legal driver head thanks to Bill. Ted and I like close racing ... so we'll see we wind up with. Might have to use the custom builts ... now that you have one. ![]()

37 January 4, 2020 10:35 pm

Re: This is the Can Am page. (116 replies, posted in Rapid Raceway)

That is an expertly built chassis from a well know builder. I also know Samson and we have shared info over the years and he has tested some of my cars on S.Cal tracks. The retro guys build Inline motor configurations because that it THEIR rules. If given a rule option like what we have ... sidewinder or even angle winder is better for handling and gear drive efficiency.

Years ago, the Retro group had huge discussions about chassis rules. They wanted to go back to 1967 car technology ... but they didn't want their cars to handle as poorly as cars ran back then. I have built several Retro chassis back in 2011 and 2012 that set track records, etc. The Retro movement died out locally in Washington after about a year.

I'll see if I can post a pic of one of my old cars.

38 November 28, 2019 12:22 pm

Re: This is the Can Am page. (116 replies, posted in Rapid Raceway)

Very nice chassis Dennis!

What keeps the front from scraping the track as you go around corners? I don't see any thing that will stop it from doing so, the rubber band does not look like it will stop it!

On light weight cars, leaning forces in the corners are minimal. That is why most all the faster race classes run on a Tri-Pod setup with no touching and rolling front tires. It is true they do lightly drag either the front bumper guards or the leading edge of the body in the turns and can be proved by the black scum accumulation on those parts.

I adjust the tension on my front axle using a Thorp fiddle stick (replica) for 3 oz. No accumulation of black scum on the bottom proves the rubber bands are doing the job. On a higher bank tho with high speeds, the front end might touch but only due to compression. Been doing rubber band suspension cars now (on scratch builds) for about 35 years.

39 October 10, 2019 8:05 pm

Re: RAPID 500 Seasoner Opener (33 replies, posted in Rapid Raceway)

One way to have more Nascar fun .... is to hold 2 Rapid 500s per year. ![]() I would drive 390 miles for it!

I would drive 390 miles for it!

40 August 23, 2019 10:39 am

Re: What's up? (97 replies, posted in Rapid Raceway)

The Porsche 962 body only weighs in at 23 grams ... minus driver/interior. A typical Nascar body and interior weighs in at 36 grams. Anyway, due to the lighter weight and lower profile, this 962 class ought to be a good handling and faster class of car. Should be a lot of fun .... on any track.

41 July 20, 2019 3:52 pm

Re: Open House & Open Track - Saturday April 27th (16 replies, posted in InSlot's Checkered Flag Raceway)

Thanks Bill, I am sure I will know by next Thursday for go or no go .... and I will let you (and Ted) know accordingly. We have some big wheel and small wheel Nascars ... and some Hawk7 powered CanAms to test. Also a late model Sportsman and Open 12 car that races down at Paul's. Don't want to burn them up .... just try a few laps to see how they like YOUR track. I know they like Howie's track.

Last summer I did nothing slot related and October really snuck up on me. This little Oregon trip will force me to prep some cars and get some momentum. To come down, all my duck have to align.

42 July 18, 2019 3:24 pm

Re: Open House & Open Track - Saturday April 27th (16 replies, posted in InSlot's Checkered Flag Raceway)

I got to run some laps here a few weeks ago. What a cool track.

Bill, you have done a top notch job getting it going!

Zack

Hi Bill, I found this Inslot raceway thread with all the pictures of potential racers. I am thinking of heading down to Oregon either tomorrow the 19th .... or Friday the 26th, to make a race in Keizer on a Saturday in July. I was wondering if there is a chance for Ted and I to stop by your track for a quick test of some new race cars? Maybe there are still too many packages laying on the track surface? Would stop by only if not inconvenient.

I have not decided (as yet) what Friday to head down that way .... and not even positive I will due to the distance. There's a part of me that wants to tho.

DC

43 May 17, 2019 8:10 am

Re: The Scholer chassis (2 replies, posted in Rapid Raceway)

Bob Nak reported he turned 391 laps in a recent Nascar race using the Scholer Striker chassis. I'm guessing that is a lap total record for that class. Impressive results for a production screw-together type frame! I have ordered one for the TA2 class.

44 April 22, 2019 8:42 pm

Re: This is the NASCAR page. (34 replies, posted in Rapid Raceway)

Sorry Howie, from now on you can bet I will buy the correct tires for the class in plenty of time before the race .... so I don't get stuck having to improvise. If I had the correct fronts ... you can bet they would be on the car.

45 April 21, 2019 4:38 pm

Re: This is the NASCAR page. (34 replies, posted in Rapid Raceway)

Results of the Apr. 20, 2019 race:

1......Gearloose..............385 laps.

2......Ted........................370

3......Bob.......................368

4......Howie....................365

5......Marty....................344

6......Scott....................237

7......Blake....................54

8......Dennis..................DQ.

For anyone not at this race, I think it is worth noting that my newly built Nascar did not have legal front tires ..... as there were none available for sale on short notice. So I used the closest facsimile in my box ... 7/8" tall fronts. The new car turned 390 laps, but now I have PLENTY of time to secure a legal set of Nascar fronts before the next race in October.

46 March 10, 2019 5:11 pm

Re: What's up? (97 replies, posted in Rapid Raceway)

I broke the front axle on my chassis last night Mitch, so you're not alone!

You broke a 1/8" size front axle? Never saw one of those break. Sometimes bend if not a full hardened drill blank. I escaped car carnage this race ... but built the chassis rails with 3/32" wire to turn it into a tank if things get ugly.

47 February 22, 2019 5:34 pm

Re: Tires drying up? (2 replies, posted in Rapid Raceway)

by howie » Thu Aug 01, 2013 10:37 am

Here is a cure for keeping tires from drying out: During the off season and anytime that a car is going to sit for awhile, I take the rear tires off and put them in a zip lock bag and put them in the freezer in the garage. I also do that with the tires that are in stock to be sold.

That appears to be a good solution .... and cheap. For years I have been applying Zip Grip tire conditioner and tossing the set of tires in tire bottles. I label the plastic lids so I know whats in there. The ZG is also adds tire traction ... if that is what you need.

48 February 22, 2019 2:38 pm

Re: What's up? (97 replies, posted in Rapid Raceway)

My Weller 80 watt soldering iron has been acting up lately. The tip usually fits fairly snugly in the ceramic holder but when I heated it up the last time, it was stuck in the holder and would not come out. Apparently a corrosion buildup. So while hot I shot WD40 in there to hopefully break up the corrosion then took pliers to the heating element and twisted gently at first .... then aggressively to get some results. Instead of coming loose, I managed to twist the ceramic holder out of the coiled wire holder. I tapped lightly on it a hundred times and the round ceramic insulator cracked into 2 parts but I finally got the iron free! After things cooled off I wire brushed the coiled wire and attempted to insert the ceramic pieces back in the coil. It worked and held together fine.

Then I heated up the iron again and ran the jaws of the pliers gently around the base of the iron tip to remove slag that has built up. Sometimes a wire brush will do the job ... but not this time. Time now to recondition the tip by bathing it with new solder and squeezing several drops from a small syringe of soldering acid to activate the re-coating procedure. The tip is looking good again and getting very hot ... but some joints require a heat gun blast first to get brass plate and wire hot before attempting to solder.

Note to self .... don't leave the iron on for long periods ... and recondition the tip often with solder and acid bathing!

49 February 19, 2019 4:31 pm

Re: This is the Sportsman page. (142 replies, posted in Rapid Raceway)

I noticed you upped your game this race DC! You increased your lap total by 16 laps over the previous race!

There is something to be said for staying in the slot during the race. I am trying to pass that info down to my trigger finger but it is a slow process. A better car tuneup also helps!

50 February 11, 2019 2:36 pm

Re: This is the Indy car page. (71 replies, posted in Rapid Raceway)

Yes, on my last post about Ted's Hawk7 motors I should have made it real clear ... I was just joking. That is why I included the smiley face.

The way to get a faster Hawk motor is to buy about 10 and only use the top 3 or so after doing a complete break in.