The first step to flattening the chassis is to make sure there is no low lying areas on the bottom of the chassis. I take a 600g nail file and just run it across the bottom surface of the chassis to reveal any low spots.

I have found that especially cars that have had axle height screws installed in the bottom, tend to have a high ridge around them. You will want to remove any very low points like this to ensure the chassis ends up flat.

Next you need a flat plate. I use a galvanized storm drain plate I got from home depot for $7 bucks. So it doesn't rust over time. Luckily all those magnets you have taken out of cars are now useable again!

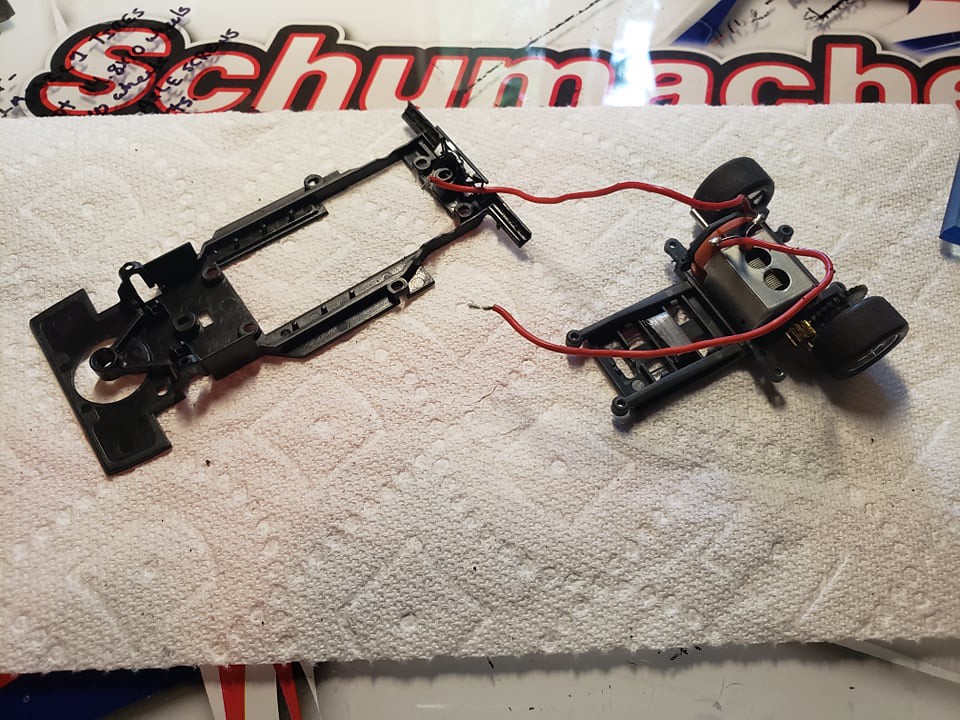

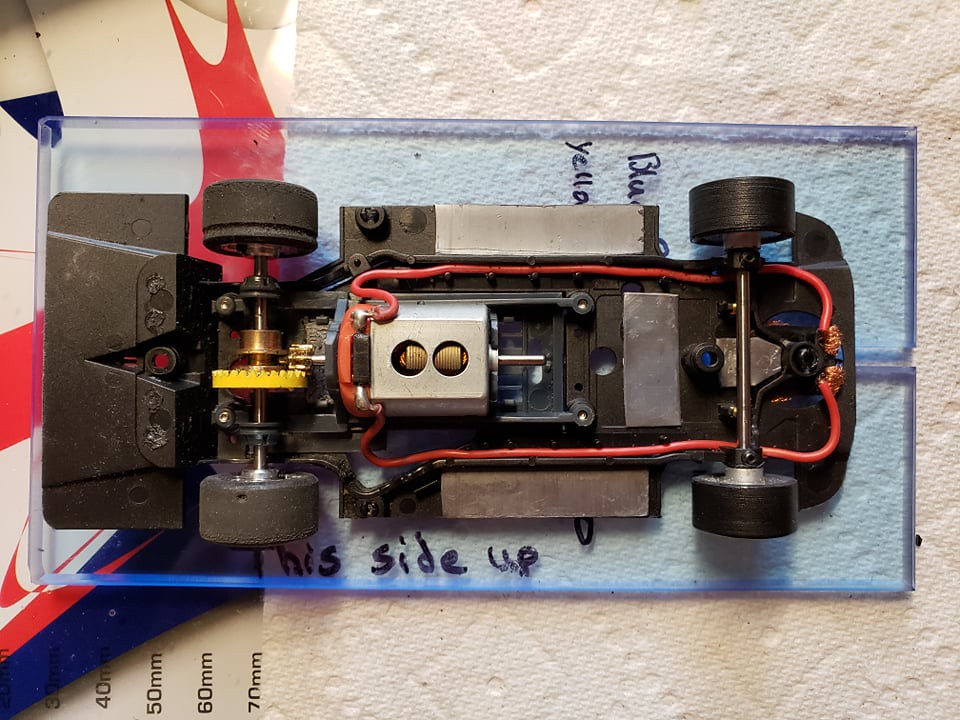

Simply stick the chassis down on the plate using many magnets. Make sure you don't have it on top of anything that will crush, and that you are not pushing the chassis one way or another, or else it will end up tweaked when your done!

I also stuck down the motor pod using all three of the magnet locations.

You want to remove the bushings from the pod when putting in water, as they tend to oxidize. The easiest way I have found on these is to just stick your allen through, turn the bushings sideways, and pry it out. Be careful it doesn't go flying!

Once you have it all prepped on the plate, it goes in oven safe dishware. As per the usual process. Preheat the oven to 230* and boil some water in a separate pot. Once the water is boiling pour it into the dishware over the chassis (i never pour directly on it, but more in the corner of the dish). Immediately after this, stick it in the oven and turn it off. Leave sit overnight (8hrs). The key here is to cool it very slowly, don't open the oven and check etc. Just wait.

The next update will be prepping the motor pod for installation of the motor and bushings. As already shown in the motor pod thread here. So may be repetitive, but I figure it will be nice having it all in order!

Zack